How can Mechanical Surveys help?

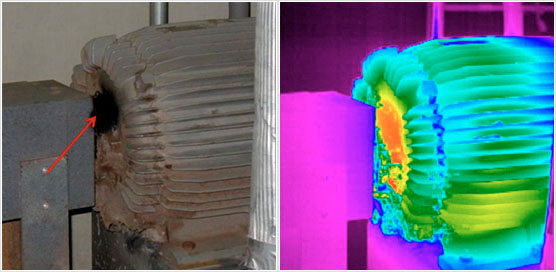

Before a mechanical component fails, excess heat from friction causes it to heat up. Infrared thermography is used to perform mechanical infrared inspections on these components to detect flaws in components before they fail.

Through state-of-the-art infrared technology, we document and provide a visual representation of non-visible component flaws for maintenance personnel. These reports prevent costly damage, safety hazards, and production downtime by allowing decision-makers to plan, schedule and correct the problem before the component fails.

Our Mechanical Infrared Testing Services

Our team has become number one in the field of Mechanical Infrared Thermography by bringing together state-of-the-art components, procedures, and experience.

Our Experience

MechaniSCAN™ thermographers have performed mechanical infrared surveys on numerous mechanical devices of all sizes and shapes. Our collection and analysis techniques have been refined over the past two decades, allowing us to provide the most relevant and valuable information to your organization.

State-Of-The-Art Equipment

We utilize the highest-resolution thermal imaging systems available to ensure you get the best possible analysis of your production equipment. This removes the need for clients to purchase their own expensive diagnostic tools. While there can be limitations to the physics of what can be seen, we are never limited by the equipment available for your project.

Documentation and Reports

Our deliverable is time proven and still makes use of cutting edge technologies, allowing for inclusion of our reports into your CMMS system.

What’s Included in our Digital Report

- Data log (A list of items inspected)

- Thermographic reports of anomalies

- Summary of findings & recap and repair guides

- Online directory of all project files

- All written/photographic information of the survey

- Ability to document repair work as it is completed

- Digital video of surveyed items